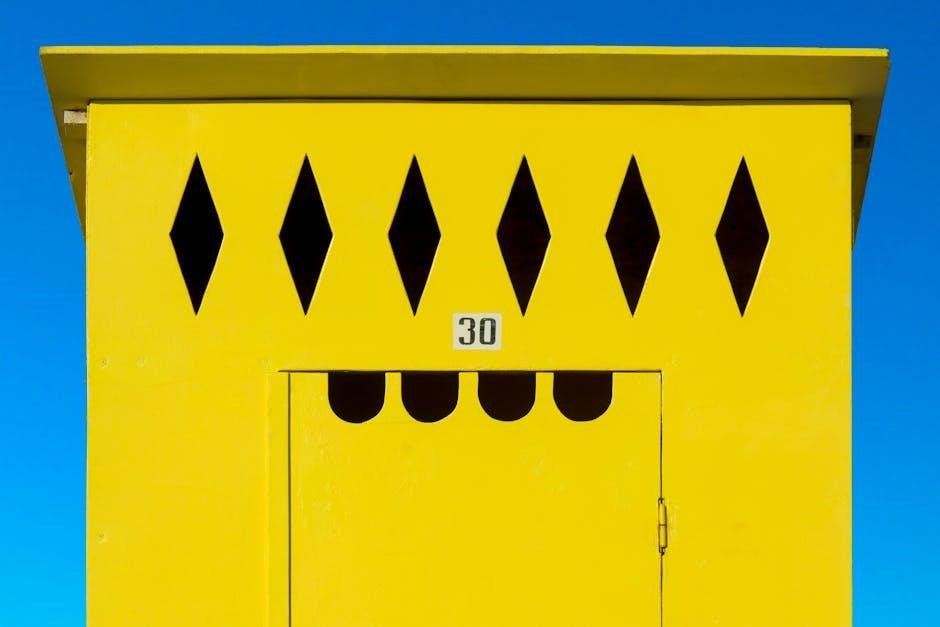

The NFPA 30 Flammable and Combustible Liquids Code provides comprehensive guidelines for the safe storage‚ handling‚ and use of flammable liquids‚ updated in the 2024 edition to address modern safety standards and emerging materials.

1.1 Overview of NFPA 30

NFPA 30 is a comprehensive standard for the safe storage‚ handling‚ and use of flammable and combustible liquids; Recognized as a widely accepted engineering practice‚ it is enforced by OSHA and various state and local regulations. The code provides detailed guidelines to minimize fire and explosion risks‚ ensuring the protection of people‚ property‚ and the environment. Key aspects include classification of liquids‚ storage requirements‚ and emergency procedures. Regular updates‚ such as the 2024 edition‚ incorporate modern safety measures and technological advancements to address evolving industry practices and hazards.

1.2 Purpose and Scope of the Standard

The purpose of NFPA 30 is to provide comprehensive safety guidelines for the storage‚ handling‚ and use of flammable and combustible liquids. Its scope covers various industries‚ including manufacturing‚ storage‚ and distribution facilities‚ ensuring the protection of people‚ property‚ and the environment. The standard applies to all facilities where such liquids are present‚ outlining minimum requirements to prevent fires‚ explosions‚ and other hazards. Compliance with NFPA 30 is enforced by OSHA and local regulations‚ making it a critical reference for ensuring safe practices and regulatory adherence.

1.3 Importance of Compliance with NFPA 30

Compliance with NFPA 30 is crucial for minimizing fire and explosion risks associated with flammable and combustible liquids. Adhering to the standard ensures the protection of people‚ property‚ and the environment by implementing proven safety practices. Non-compliance can lead to severe penalties‚ legal liabilities‚ and increased risks of accidents. NFPA 30 compliance also aligns with OSHA and local regulations‚ ensuring a safer workplace and reducing potential environmental damage. By following the guidelines‚ facilities can prevent hazards‚ maintain operational efficiency‚ and uphold their commitment to safety and environmental responsibility.

Scope and Application

NFPA 30 applies to industries handling flammable and combustible liquids‚ providing guidelines for safe storage‚ use‚ and transportation. It covers manufacturing‚ storage facilities‚ and transportation‚ ensuring compliance with OSHA and local regulations to mitigate fire hazards.

2.1 Industries Covered by NFPA 30

NFPA 30 applies to various industries‚ including manufacturing‚ chemical plants‚ oil refineries‚ fuel distribution centers‚ and any facility storing or handling flammable or combustible liquids. It is enforceable under OSHA and state regulations‚ ensuring safety in industrial settings. The code covers industries where flammable liquids are used‚ stored‚ or processed‚ making it a critical standard for preventing fire hazards in both large-scale and smaller operations. Its broad application ensures comprehensive safety measures across diverse industrial sectors.

2.2 Types of Liquids and Substances Regulated

NFPA 30 regulates flammable and combustible liquids based on their fire hazards. Class I liquids have flash points below 73.4°F‚ Class II between 73.4°F and 140°F‚ and Class III above 140°F. The standard also addresses substances like gasoline‚ diesel‚ and industrial solvents. The 2024 edition introduces updated classifications for emerging materials‚ ensuring accurate risk assessment. These categories help determine appropriate storage‚ handling‚ and safety measures‚ aligning with industry practices and hazard mitigation strategies.

2.3 Regulatory Framework and Enforcement

NFPA 30 is enforced by OSHA and state/local regulations‚ ensuring compliance with safety standards for flammable and combustible liquids. It is recognized as a RAGAGEP‚ making it a critical enforcement tool. Regulatory bodies conduct inspections to verify adherence to storage‚ handling‚ and use requirements. The 2024 edition aligns with updated safety protocols‚ incorporating technological advancements and environmental considerations. Compliance is mandatory to mitigate fire and explosion risks‚ safeguarding both people and the environment. Enforcement ensures that facilities implement proper safety measures and maintain required documentation.

Classification of Flammable and Combustible Liquids

NFPA 30 classifies liquids based on flash points and boiling points‚ with updated 2024 classifications for emerging materials‚ ensuring accurate risk assessment and safety measures.

3.1 Class I‚ II‚ and III Liquids

NFPA 30 classifies flammable and combustible liquids into three categories based on their flash points and boiling points. Class I liquids‚ with flash points below 73.4°F‚ are highly flammable and pose significant risks. Class II liquids have flash points between 73.4°F and 140°F‚ while Class III liquids‚ divided into IIIA (flash point < 140°F to < 200°F) and IIIB (flash point ≥ 200°F)‚ are less hazardous. These classifications guide safe handling‚ storage‚ and emergency response strategies‚ ensuring compliance with safety standards and minimizing fire risks. The 2024 edition refines these categories to address new materials and technologies.

3.2 Flash Point and Boiling Point Criteria

NFPA 30 defines flammable and combustible liquids based on flash point and boiling point criteria. Flash point determines a liquid’s flammability‚ with lower values indicating higher hazards. Boiling point influences vapor pressure and fire risk. The 2024 edition refines these criteria to align with modern safety standards‚ ensuring accurate classification and risk assessment. These criteria are essential for proper storage‚ handling‚ and emergency response‚ helping to mitigate fire and explosion risks in industrial and commercial settings. Updates enhance clarity and safety for diverse liquid types and applications.

3.4 Updated Classification System in the 2024 Edition

The 2024 edition of NFPA 30 introduces an updated classification system for flammable and combustible liquids‚ providing more precise categories to address emerging materials. This revision ensures classifications align with current industry practices and risk levels‚ enhancing safety measures. The updated system includes new provisions for substances with unique properties‚ improving hazard identification and management. These changes reflect advancements in technology and environmental considerations‚ ensuring safer handling and storage practices; Industries must adapt to these revised classifications to maintain compliance and reduce risks effectively.

Storage Requirements

NFPA 30 outlines specific guidelines for safely storing flammable and combustible liquids‚ including tank design‚ container specifications‚ and separation distances to mitigate fire risks and ensure environmental protection.

4.1 General Storage Guidelines

NFPA 30 provides detailed guidelines for the safe storage of flammable and combustible liquids‚ emphasizing proper tank and container design‚ material compatibility‚ and secure locations. Storage areas must be well-ventilated‚ protected from ignition sources‚ and isolated from incompatible materials. Tanks should be constructed of approved materials‚ such as steel‚ and designed to withstand internal pressures. Indoor storage requires additional safeguards‚ including spill containment and ventilation systems. Outdoor storage must comply with separation distances and environmental protection measures. Regular inspections and maintenance are essential to ensure compliance and safety.

4.2 Tank Storage and Design Requirements

NFPA 30 specifies that tanks storing flammable and combustible liquids must be designed and constructed to withstand internal pressures and external stresses. Tanks should be made of materials like steel‚ resistant to corrosion and compatible with the stored liquid. Design requirements include reinforced construction‚ secure closures‚ and adequate venting to prevent overpressure. The 2024 edition emphasizes enhanced testing and inspection protocols to ensure tank integrity. Secondary containment systems are mandated to prevent environmental contamination in case of leaks or spills. Tanks must also be protected from external hazards such as weather conditions and physical impacts.

4.3 Container and Portable Tank Specifications

NFPA 30 outlines strict specifications for containers and portable tanks used to store flammable and combustible liquids. Containers must be designed and constructed to ensure tightness‚ strength‚ and compatibility with the liquids they hold. They should be made of durable materials‚ such as steel or approved plastics‚ with adequate thickness to prevent leakage or rupture. Seals and closures must be secure to prevent vapors or liquids from escaping. Portable tanks must also meet specific design and safety standards‚ including proper venting and labeling. The 2024 edition emphasizes enhanced testing and inspection requirements to ensure compliance and safety.

4.4 Distance Requirements and Separation

NFPA 30 establishes specific distance requirements for the separation of storage areas‚ containers‚ and portable tanks from other facilities‚ ignition sources‚ and property lines. These distances vary based on the classification of liquids‚ storage capacity‚ and type of containers or tanks. The 2024 edition includes updated separation criteria to account for new materials and technologies‚ ensuring enhanced fire safety and risk mitigation. Compliance with these requirements is critical to prevent fire spread and protect nearby structures and populations from potential hazards associated with flammable and combustible liquids.

Handling and Use of Flammable Liquids

NFPA 30 provides detailed guidelines for the safe handling and use of flammable liquids‚ emphasizing proper dispensing procedures and the use of approved safety containers.

5.1 Safe Handling Practices

NFPA 30 emphasizes safe handling practices to minimize fire and explosion risks. Proper training‚ use of personal protective equipment (PPE)‚ and adherence to spill control measures are essential. Real-time monitoring systems enhance safety by detecting potential hazards early. Regular inspections and maintenance of equipment ensure compliance with safety standards. Employers must train employees on emergency procedures and proper handling techniques. Updated provisions in the 2024 edition focus on advanced technologies‚ such as leak detection‚ to improve safety protocols and reduce risks associated with flammable liquids.

5.2 Dispensing and Transfer Procedures

NFPA 30 outlines detailed procedures for the safe dispensing and transfer of flammable liquids. Proper equipment‚ such as safety cans and tightly sealed containers‚ must be used to prevent spills and leaks. The 2024 edition emphasizes enhanced safety measures‚ including secondary containment systems and real-time monitoring technologies. Training on dispensing protocols is critical to ensure compliance and minimize risks. Regular inspections of transfer equipment and adherence to updated guidelines further ensure safe operations‚ aligning with modern safety standards and reducing potential hazards during liquid handling.

5.3 Use of Safety Cans and Containers

The use of safety cans and containers is critical for storing and handling flammable liquids. NFPA 30 specifies that safety cans must have tight seals to prevent spills and leaks. Containers should be designed with flame arrestors to prevent ignition sources from entering. The 2024 edition emphasizes the use of containers made from materials compatible with the liquids being stored. Proper labeling and regular inspection of containers are required to ensure compliance. Safety cans are limited to a maximum capacity of 2 gallons for Class I liquids‚ as per OSHA regulations. Adherence to these guidelines minimizes fire risks and ensures safe operations.

Fire Protection Systems

NFPA 30 outlines fire protection systems for flammable liquids‚ including fire suppression‚ sprinkler systems‚ and foam suppression. These systems help mitigate risks and prevent fire escalation‚ ensuring compliance with safety standards.

6.1 Fire Suppression Systems

Fire suppression systems are critical in mitigating fire hazards involving flammable liquids. NFPA 30 requires the use of approved suppression systems‚ such as foam‚ clean agent‚ or sprinkler systems‚ tailored to the specific risks of the facility. These systems must be designed and installed to prevent fire escalation and protect personnel and assets. Compliance with NFPA 30 ensures that suppression systems are effective‚ reliable‚ and maintained according to industry standards‚ addressing the unique challenges posed by flammable and combustible liquids in various industrial settings.

6.2 Sprinkler Systems and Foam Suppression

Sprinkler systems and foam suppression are essential components of fire protection in facilities handling flammable liquids. NFPA 30 specifies that sprinkler systems must be designed to cover all hazardous areas‚ with discharge rates sufficient to control fires involving flammable liquids. Foam suppression systems are particularly effective for fires involving Class B flammable liquids‚ providing a barrier to prevent reignition. The 2024 edition emphasizes enhanced design criteria for foam systems and compatibility with modern storage practices‚ ensuring these systems remain effective and compliant with updated safety standards.

6.3 Fire Detection and Alarm Systems

Fire detection and alarm systems play a critical role in early fire identification and response. NFPA 30 requires these systems to be installed in areas where flammable liquids are stored or handled‚ ensuring timely alerts and mitigating potential hazards. The 2024 edition emphasizes the integration of advanced detection technologies‚ such as smoke and heat sensors‚ to enhance reliability. Additionally‚ systems must be tested regularly to ensure compliance and effectiveness. These measures are vital for safeguarding personnel‚ assets‚ and the environment from fire-related risks in high-hazard environments.

Spill Control and Environmental Considerations

NFPA 30 emphasizes spill prevention‚ control‚ and environmental mitigation to minimize ecological damage. It outlines strategies for containment‚ cleanup‚ and waste management‚ ensuring compliance with safety and environmental regulations.

7.1 Spill Prevention and Control Measures

NFPA 30 provides detailed guidelines for spill prevention and control‚ emphasizing proactive measures to minimize environmental impact; It recommends secondary containment systems‚ regular inspections‚ and employee training to handle potential spills effectively. The standard also advocates for the use of safety cans‚ proper container storage‚ and immediate cleanup procedures to prevent hazardous situations. Advanced technologies‚ such as real-time leak detection‚ are encouraged to enhance early warning systems. These measures ensure compliance with environmental regulations while reducing risks associated with flammable and combustible liquids.

7.2 Secondary Containment Systems

NFPA 30 mandates the use of secondary containment systems to prevent environmental contamination from spills or leaks. These systems must be designed to hold at least 110% of the tank’s capacity‚ ensuring adequate storage for potential releases. The standard specifies requirements for construction materials‚ ensuring they are durable and impermeable to hazardous liquids. Regular inspections and maintenance are required to guarantee the integrity of these systems. Proper implementation of secondary containment is critical for protecting soil and groundwater from contamination‚ aligning with environmental protection goals outlined in the code.

7.3 Environmental Impact Mitigation

NFPA 30 emphasizes environmental protection by integrating advanced spill control measures and detection systems to minimize ecological damage. The 2024 edition introduces real-time monitoring technologies to quickly identify and address potential leaks‚ preventing hazardous releases. Regular inspections of containment systems ensure their effectiveness. These measures aim to safeguard surrounding ecosystems and reduce contamination risks‚ aligning with broader environmental protection goals.

Technological Advancements in NFPA 30

The 2024 edition of NFPA 30 introduces real-time leak detection systems‚ advanced monitoring technologies‚ and automation in hazard detection‚ enhancing safety and efficiency in handling flammable liquids.

8.1 Real-Time Leak Detection Systems

The 2024 edition of NFPA 30 emphasizes the implementation of real-time leak detection systems to enhance safety in facilities handling flammable liquids. These advanced systems provide immediate alerts for potential leaks‚ enabling rapid response to mitigate hazards. By integrating sensors and monitoring technologies‚ they reduce the risk of fire and environmental damage. Real-time data ensures proactive maintenance and compliance with safety standards‚ making these systems a critical component of modern hazard management strategies in industrial settings.

8.2 Integration of Advanced Monitoring Technologies

NFPA 30’s 2024 edition highlights the integration of advanced monitoring technologies to enhance safety and efficiency in handling flammable liquids. These technologies include real-time data collection‚ wireless sensors‚ and predictive analytics‚ enabling proactive hazard detection and risk reduction. By automating surveillance‚ facilities can identify potential issues before incidents occur‚ ensuring compliance with safety standards. These advancements align with modern industrial practices‚ promoting a safer working environment and minimizing operational disruptions. The integration of such technologies underscores NFPA 30’s commitment to leveraging innovation for improved fire and hazard management.

8.3 Use of Automation in Hazard Detection

The 2024 NFPA 30 edition emphasizes automation’s role in enhancing hazard detection‚ ensuring timely identification and mitigation of risks. Advanced systems‚ including smart sensors and IoT devices‚ continuously monitor storage areas for leaks‚ temperature fluctuations‚ and vapour buildup. These automated solutions provide real-time alerts‚ enabling faster response to potential hazards. By integrating data analytics‚ automation can predict potential incidents‚ reducing risks proactively. This technological advancement aligns with modern safety practices‚ ensuring a safer and more efficient management of flammable and combustible liquids in industrial settings.

Compliance and Enforcement

NFPA 30 is enforceable under OSHA regulations and state/local laws‚ ensuring adherence to safety standards for flammable liquids. Compliance requires regular inspections and detailed record-keeping.

9.1 OSHA Regulations and NFPA 30

NFPA 30 is recognized as a key standard by OSHA‚ incorporated into federal regulations like 29 CFR 1910.106. OSHA enforces NFPA 30 guidelines to ensure safe handling and storage of flammable liquids in workplaces. Employers must comply with NFPA 30 requirements for storage‚ handling‚ and use of flammable liquids to meet OSHA standards. Regular inspections and adherence to NFPA 30 provisions help prevent hazards and ensure legal compliance. OSHA also references NFPA 30 in its enforcement of safety practices‚ making it a critical document for workplace safety.

9.2 Local and State Compliance Requirements

Local and state authorities enforce NFPA 30 through specific regulations‚ often integrating it into building codes‚ fire safety ordinances‚ and environmental protection laws. Compliance requirements may vary by jurisdiction‚ with some states adopting the standard in full while others add supplementary rules. Facilities must adhere to these local regulations‚ which often include permits‚ inspections‚ and specific safety measures. Failure to comply can result in penalties‚ shutdowns‚ or legal action. Staying informed about local and state updates is essential to ensure full compliance with NFPA 30 and avoid enforcement issues.

9.3 Record-Keeping and Inspection Requirements

NFPA 30 mandates detailed record-keeping for storage‚ handling‚ and use of flammable liquids. Facilities must maintain documentation‚ including training records‚ inspection logs‚ and compliance audits. Regular internal inspections are required to ensure adherence to safety standards‚ with findings documented and addressed promptly. Third-party audits may also be necessary to verify compliance. Proper record-keeping ensures accountability and helps during regulatory reviews. Digital tools can streamline this process‚ providing accessible and organized records for authorities. Accurate and up-to-date records are critical for maintaining safety and avoiding enforcement actions.

Training and Emergency Procedures

NFPA 30 emphasizes employee training on handling flammable liquids‚ emergency response planning‚ and conducting regular fire evacuation drills to ensure workplace safety and compliance with regulations.

10.1 Employee Training Requirements

NFPA 30 mandates comprehensive training for employees handling flammable liquids‚ ensuring they understand safe practices‚ emergency procedures‚ and the use of safety equipment. Training must be provided upon hiring and updated annually to reflect current standards and potential hazards. Topics include proper handling techniques‚ spill response‚ fire extinguisher operation‚ and compliance with NFPA 30 guidelines. Employers must maintain records of training sessions to verify compliance. This ensures a well-prepared workforce capable of mitigating risks effectively in real-world scenarios‚ aligning with the standard’s emphasis on safety and regulatory adherence.

10.2 Emergency Response Planning

NFPA 30 requires facilities to develop and implement a detailed emergency response plan to address incidents involving flammable liquids. The plan must include procedures for spills‚ leaks‚ fires‚ and evacuations‚ ensuring timely and effective action. Regular drills and training are mandated to familiarize personnel with emergency protocols. Coordination with local fire departments and emergency services is essential to enhance response capabilities. The plan should also incorporate advanced technologies‚ such as real-time leak detection systems‚ to improve incident response. Compliance with these requirements ensures preparedness and minimizes risks during emergencies‚ aligning with NFPA 30’s focus on safety and environmental protection.

10.3 Fire Evacuation and Safety Drills

NFPA 30 mandates regular fire evacuation and safety drills to ensure preparedness in emergencies. These drills must be conducted at least annually and involve all personnel to familiarize them with escape routes‚ emergency exits‚ and assembly points. The plan should include procedures for accounting for all individuals after evacuation. Drills must simulate real-world scenarios‚ such as fires or spills‚ to test the effectiveness of the evacuation process. Documentation of drills‚ including participation and outcomes‚ is required to ensure compliance and identify areas for improvement. This helps maintain a safe and responsive environment.

Updates in the 2024 Edition

The 2024 edition of NFPA 30 introduces real-time leak detection systems‚ advanced monitoring technologies‚ and automation in hazard detection to enhance safety and compliance standards.

11.1 Key Changes and Revisions

The 2024 edition of NFPA 30 includes significant updates‚ such as the integration of real-time leak detection systems and advanced monitoring technologies. It revises the classification system for flammable liquids‚ enhancing safety measures for storage and handling. New provisions address emerging materials and substances‚ ensuring alignment with modern industrial practices. The updated code also emphasizes environmental protection through improved spill control and secondary containment systems. These changes reflect a focus on technological advancements‚ hazard mitigation‚ and compliance with current safety standards‚ providing a robust framework for managing flammable and combustible liquids effectively.

11.2 Enhanced Safety Measures

The 2024 edition of NFPA 30 introduces enhanced safety measures‚ including updated provisions for storage and handling of flammable liquids. It strengthens requirements for distance separation‚ spill control‚ and secondary containment systems to minimize risks. The code now emphasizes the use of advanced fire suppression systems‚ such as foam and sprinkler systems‚ tailored to specific hazards. Additionally‚ it integrates real-time leak detection and automation technologies to improve early warning and response capabilities. These enhancements aim to reduce fire and explosion hazards while aligning with modern industrial practices and environmental considerations.

11.3 New Provisions for Emerging Materials

The 2024 edition of NFPA 30 addresses emerging materials with revised classification systems for flammable and combustible liquids. It introduces more specific categories to align with current industry practices and risks. New provisions focus on addressing unique properties of modern substances‚ ensuring safer handling and storage. The updates also include guidelines for real-time monitoring and automation in detecting hazards related to these materials. These changes reflect the evolving landscape of hazardous materials and aim to mitigate risks associated with their use in industrial settings while promoting environmental and safety compliance.

NFPA 30 provides critical safety standards for flammable and combustible liquids‚ ensuring compliance with updated regulations and emerging technologies to enhance safety and environmental protection in industrial settings.

12.1 Summary of NFPA 30 Requirements

NFPA 30 establishes essential guidelines for the safe storage‚ handling‚ and use of flammable and combustible liquids. It classifies liquids based on their fire hazards‚ outlines storage and handling practices‚ and specifies fire protection measures. The code also addresses spill control‚ secondary containment‚ and emergency response planning. Compliance with NFPA 30 is critical for minimizing fire risks‚ protecting the environment‚ and ensuring regulatory adherence. Regular updates‚ such as those in the 2024 edition‚ incorporate advancements in technology and safety practices to maintain robust protection standards across industries.

12.2 Importance of Staying Updated

Staying updated with the latest edition of NFPA 30 is crucial for ensuring compliance with current safety standards and regulations. The 2024 edition introduces revised classifications‚ enhanced safety measures‚ and new provisions for emerging materials‚ reflecting the evolving landscape of hazardous material management. Regular updates ensure that facilities adopt the most effective practices to mitigate risks and protect people and the environment. By staying informed‚ organizations can maintain compliance‚ reduce potential hazards‚ and align with advancements in technology and industry practices‚ ultimately enhancing overall safety and operational efficiency.

12.3 Final Thoughts on Compliance and Safety

Compliance with NFPA 30 is essential for preventing fire hazards and protecting both people and the environment. Adhering to the code ensures facilities operate safely and responsibly. Continuous improvement in safety practices‚ as outlined in the latest editions‚ is vital for managing risks effectively. Organizations must prioritize compliance to prevent accidents‚ reduce liability‚ and foster a culture of safety. Non-compliance can lead to severe consequences‚ including legal penalties and reputational damage. By staying proactive‚ they can safeguard their operations and contribute to a safer‚ more sustainable future.

Leave a Reply

You must be logged in to post a comment.